- Manual Paper Core Cutting Machines

- Semi Automatic Core Cutter Machine

- Semi Automatic Core Cutter Machine with CE Covers

- Reel Lifting Equipments

- Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

- Inline Printers

- Plastic Bag Corona Treater

- Woven Bag Corona Treater

- Plastic Granule Mixer

- HDPE-LDPE Recycing Machine

- Inline - Offline Edge Trim Waste Recycling Machine

- Cold Perforation Roller

- Cold Perfotaion Roller With Brush Roller

- Rollers/Cylinders

- 2 Colours Flexo Printing Machine

- Duplex System Slitter Rewinder Machine

- Pocket Attaching Equipment for Courier Bag Making Machines

- Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

- Auto Vacuum Loader

- Trim Waste Rewinder For Extruders

- Accessories

- Spare Parts

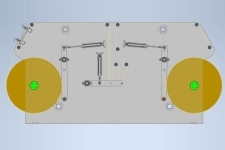

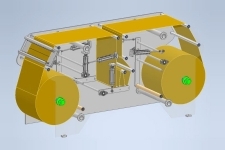

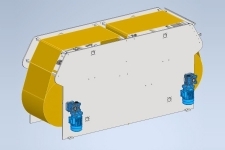

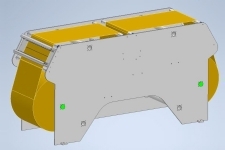

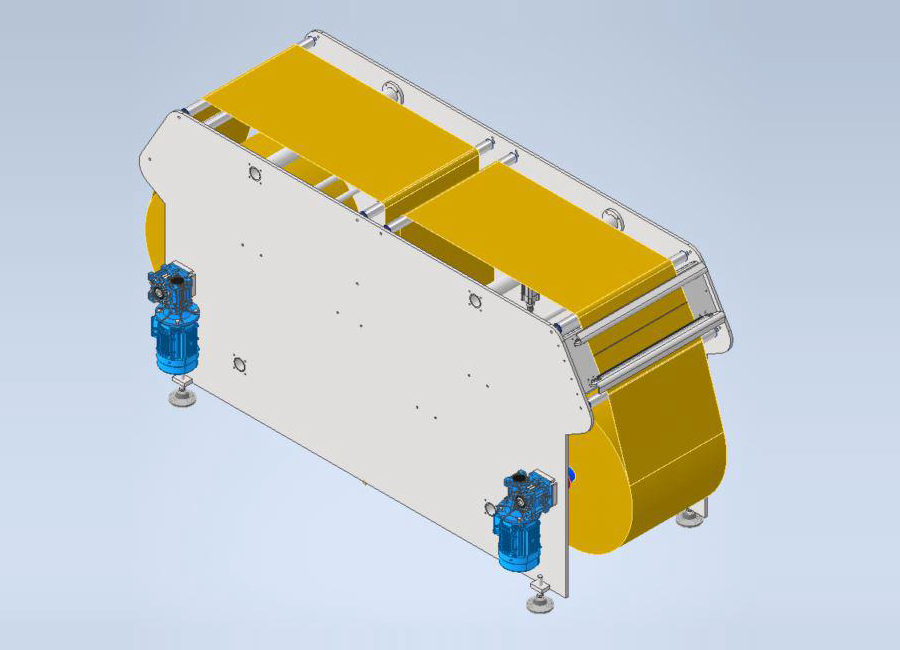

Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

-

Description

-

Automatic Film Inspection, Tension Correction and Rewinding

Key Features ✔ Fully Automatic Unwinding & Rewinding

The Roll to Roll Unwinding & Rewinding Machine, also known as a Doctoring Machine, is designed to inspect, correct, and reprocess film rolls by unwinding and rewinding them with precise control. It is widely used in flexible packaging, plastic film production, printing, and converting industries, ensuring flawless roll quality.

The machine performs automatic web unwinding and rewinding, ensuring smooth film handling and stable operation throughout the process.

✔ Tension Error Correction

If the incoming roll has tension irregularities, the system adjusts and corrects the tension during rewinding, producing a perfectly wound roll.

✔ Edge Alignment Correction

For rolls with poor edge profile or misalignment, the machine corrects the edge position, ensuring a clean and uniform roll structure.

✔ Start/Stop Operating Capability

The operator can easily stop and restart the machine at any point without causing film damage or tension loss.

✔ Pneumatic Film Locking & Cutting Unit

Located after the unwinder section, this unit allows the operator to:

- Lock the film pneumatically

- Cut and remove defective film sections

- Rejoin the film quickly and safely

This feature is ideal for removing defects such as wrinkles, print errors, holes, or contamination.

The machine can be configured with:

- Pneumatic tension control, or

- Load-cell-based closed-loop tension control

depending on the customer’s production requirements.

The machine width is custom-designed according to the film roll size and production needs.

✔ High-Performance Drive Options

- AC motor drive supports rolls up to 300 mm diameter

- For larger diameters and advanced precision, a servo motor drive can be integrated based on customer specifications

This ensures perfect rewinding quality even at high speeds.

- Corrects tension and edge errors in pre-wound rolls

- Allows removal of defective film sections

- Enhances roll quality for downstream processes such as printing, slitting, or bag making

- Improves production efficiency and reduces waste

- Customizable design for any film type or roll size

- Safe and simple operation with minimal maintenance

- Flexible packaging manufacturers

- Plastic film extrusion lines

- Printing and laminating lines

- Slitting and converting operations

- Quality control and inspection departments

-

-

Photo Gallery

web design grimor