How can we help you?

MACHINES AND ANCILLARY EQUIPMENTS

- Manual Paper Core Cutting Machines

- Semi Automatic Core Cutter Machine

- Semi Automatic Core Cutter Machine with CE Covers

- Reel Lifting Equipments

- Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

- Inline Printers

- Plastic Bag Corona Treater

- Woven Bag Corona Treater

- Plastic Granule Mixer

- HDPE-LDPE Recycing Machine

- Inline - Offline Edge Trim Waste Recycling Machine

- Cold Perforation Roller

- Cold Perfotaion Roller With Brush Roller

- Rollers/Cylinders

- 2 Colours Flexo Printing Machine

- Duplex System Slitter Rewinder Machine

- Pocket Attaching Equipment for Courier Bag Making Machines

- Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

- Auto Vacuum Loader

- Trim Waste Rewinder For Extruders

- Accessories

- Spare Parts

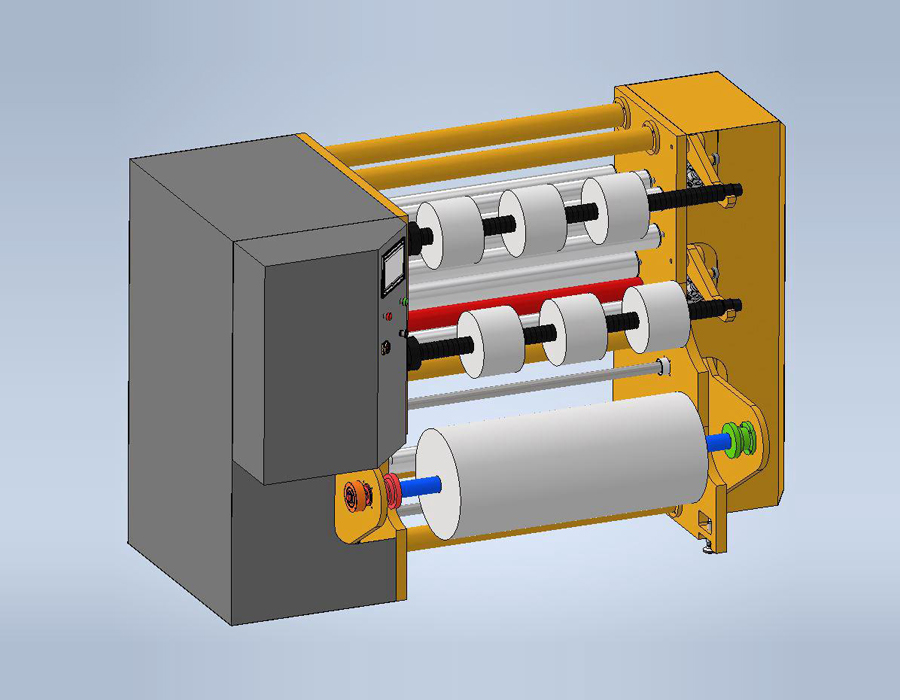

Duplex System Slitter Rewinder Machine

» Machine Model: EMS-1300

» Machine Model: EMS-1300 » Machine Name: SLITTER AND REWINDER MACHINE

-

Description

-

High-Speed Slitting & Precision Rewinding System (1200 mm Material Width)

Technical Specifications & Features

The EMS-1300 Slitter and Rewinder Machine is engineered for high-precision slitting and stable rewinding of various plastic films, laminates, and flexible packaging materials. With advanced servo-driven technology and intelligent tension control, the machine ensures outstanding roll quality at high production speeds.Machine Structure

- Material Working Width: 1200 mm

- Idler Roller Width: 1300 mm

- Main Roller: Rubber-coated roller + chrome-plated metal roller driven by servo motor

- Rewinder: Two rewinder sections, each equipped with servo-driven friction shafts

- Total Servo Motors in Rewinder: 2 pcs

- Mechanical Speed: 400 m/min

- Actual Working Speed: Depends on material quality, thickness, and operating conditions

- Magnetic Powder Brake System for stable tension

- Automatic Edge Guidance System (EPC)

- 1 pc Air Shaft (3” / 76 mm) – strong & high-speed resistant

- Safety Chucks on unwinder for secure and reliable shaft locking

- Two Friction Shafts allowing multiple finished rolls

- Servo Torque Mode: Automatic tension control on each rewinder shaft

- Ensures perfect slitting and flawless roll formation

- Rewinder: Servo torque-controlled automatic tension

- Unwinder: Load-cell-based automatic tension control

- Ability to use:

- 10 pcs straight (razor) knives

- 5 pcs round (rotary) knives

- Flexible configuration for various film types and widths

- Edge Trim Vacuum Blowing System for clean and continuous operation

- 10-inch Touch Screen HMI with user-friendly interface

- Centralized control for speed, tension, knives, and alignment

- High-speed and stable slitting at up to 400 m/min

- Servo-driven accuracy ensures perfect roll density and profile

- Multi-reel production improves efficiency and reduces downtime

- Advanced tension control for sensitive and high-quality films

- Robust mechanical structure designed for long-term operation

-

-

Photo Gallery

info@elesmakina.com

Eles Plastik Makina Otomasyon San ve Tic Ltd. Şti. © All Rights Reserved.

web design grimor

web design grimor

MACHINES AND ANCILLARY EQUIPMENTS

» Manual Paper Core Cutting Machines

» Semi Automatic Core Cutter Machine

» Semi Automatic Core Cutter Machine with CE Covers

» Reel Lifting Equipments

» Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

» Inline Printers

» Plastic Bag Corona Treater

» Woven Bag Corona Treater

» Plastic Granule Mixer

» HDPE-LDPE Recycing Machine

» Inline - Offline Edge Trim Waste Recycling Machine

» Cold Perforation Roller

» Cold Perfotaion Roller With Brush Roller

» Rollers/Cylinders

» 2 Colours Flexo Printing Machine

» Duplex System Slitter Rewinder Machine

» Pocket Attaching Equipment for Courier Bag Making Machines

» Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

» Auto Vacuum Loader

» Trim Waste Rewinder For Extruders

» Accessories

» Spare Parts