- Manual Paper Core Cutting Machines

- Semi Automatic Core Cutter Machine

- Semi Automatic Core Cutter Machine with CE Covers

- Reel Lifting Equipments

- Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

- Inline Printers

- Plastic Bag Corona Treater

- Woven Bag Corona Treater

- Plastic Granule Mixer

- HDPE-LDPE Recycing Machine

- Inline - Offline Edge Trim Waste Recycling Machine

- Cold Perforation Roller

- Cold Perfotaion Roller With Brush Roller

- Rollers/Cylinders

- 2 Colours Flexo Printing Machine

- Duplex System Slitter Rewinder Machine

- Pocket Attaching Equipment for Courier Bag Making Machines

- Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

- Auto Vacuum Loader

- Trim Waste Rewinder For Extruders

- Accessories

- Spare Parts

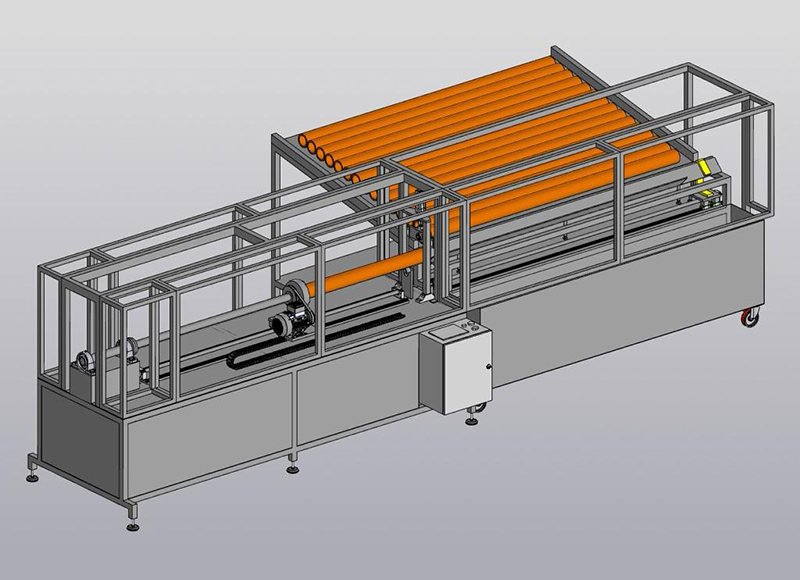

Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

FULLY AUTOMATIC PAPER CORE CUTTING MACHINE

FULLY AUTOMATIC PAPER CORE CUTTING MACHINEAUTO LOADING + AUTO UNLOADING SYSTEM

-

Description

-

1. GENERAL DESCRIPTION

A fully automatic paper core cutting solution designed for high-speed, precise, and continuous cutting of paper cores up to 2 meters length. Machine is equipped with:

· Automatic core loading

· Automatic cutting with PLC + servo control

· Automatic core unloading

· Pneumatic & servo-driven hybrid systems

· Mitsubishi (Japan) control components

Best suited for flexible packaging, film converting, slitting, and paper tube converting industries.

2. TECHNICAL FEATURES

Cutting Performance

· Maximum cutting thickness (one side): Up to 15 mm

· Cutting length capacity: 2 meters

· Cutting travel length: 2 meters effective cutting zone

· Cutting method:

o Vertical, pneumatic round-knife cutting system

o Optional servo-driven cutting knife for higher precision

· Knife support:

o Polyamide (PA) support under the knife → longer knife life

· Cutting depth adjustment:

o Mechanical limiter ensures precise cutting depth to polyamide surface

Core Loading System

· Pneumatic Loader selects and picks a single core from the storage container

· Loading is servo motor driven + pneumatic combination

· Max core length: 2 meters

· Automatic alignment during loading

Core Rotation & Holding

· Three-phase AC motor drives the rotation of the paper cores (via belt pulley system)

· Pneumatic Core Keeper System locks the paper core during rotation

· Metal shaft covered with polyamide at the knife zone

Mechanical Support Systems

· Mechanical support under the shaft to prevent sagging of heavy and long cores

· Mechanical limiter for horizontal adjustment of the shaft

· Knife mechanical limiter provides stable cutting depth control

Cutting Positioning System

· Cutting positions set via touch screen (HMI)

· Servo Motor Driven Positioning for exact cut lengths

· PLC-controlled automatic movement

· Cutting positioning accuracy ensured by Mitsubishi:

o PLC

o Touch Screen Panel

o Servo Motor & Servo Drivers

Control System

· Full automation via Mitsubishi (Japan) electronic control package

· Parameters entered directly from the touch screen

· Fully automatic operation cycle

3. WORKING SYSTEM – PROCESS EXPLANATION

1. Auto Loading:

o Pneumatic Loader picks one paper core from the storage magazine.

o Pneumatic Core Keeper locks the core in position.

o Servo-driven carriage moves to the opposite end of the shaft, loading the full 2-meter core.

2. Positioning:

o Carriage moves according to the preset cut lengths on the touch screen.

o Positioning is servo-driven for maximum precision.

3. Cutting:

o Round knife moves vertically (pneumatic or servo option) and performs the cut.

o Knife depth is controlled by mechanical limiter + polyamide support.

4. Auto Unloading:

o Each cut core piece is transferred to the unloading area.

o Unloader drops the cut pieces into the front collection container.

5. Completion of Cycle:

o When the full 2-meter core is fully consumed → Cutting cycle is completed.

o Machine automatically returns to the starting position and prepares for loading the next core.

4. KEY ADVANTAGES

· Fully automatic loading → no manual core insertion

· Fully automatic cutting → high speed and safety

· Fully automatic unloading → continuous production without operator effort

· Servo-driven precision cutting positions

· Longer knife life via polyamide support system

· Mitsubishi electronic control package for maximum stability

· Mechanical shaft support prevents bending/sagging

· High cutting accuracy and stable repeatability

-

-

Photo Gallery

web design grimor