How can we help you?

MACHINES AND ANCILLARY EQUIPMENTS

- Manual Paper Core Cutting Machines

- Semi Automatic Core Cutter Machine

- Semi Automatic Core Cutter Machine with CE Covers

- Reel Lifting Equipments

- Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

- Inline Printers

- Plastic Bag Corona Treater

- Woven Bag Corona Treater

- Plastic Granule Mixer

- HDPE-LDPE Recycing Machine

- Inline - Offline Edge Trim Waste Recycling Machine

- Cold Perforation Roller

- Cold Perfotaion Roller With Brush Roller

- Rollers/Cylinders

- 2 Colours Flexo Printing Machine

- Duplex System Slitter Rewinder Machine

- Pocket Attaching Equipment for Courier Bag Making Machines

- Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

- Auto Vacuum Loader

- Trim Waste Rewinder For Extruders

- Accessories

- Spare Parts

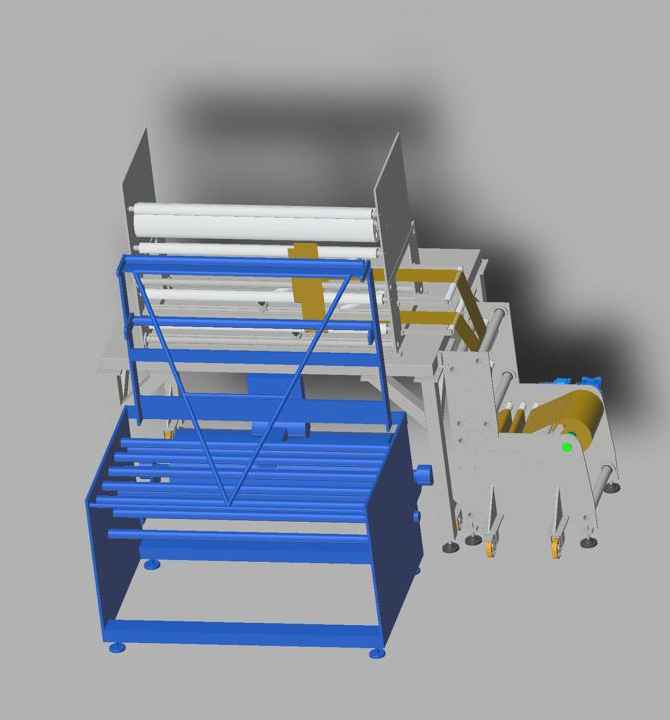

Pocket Attaching Equipment for Courier Bag Making Machines

-

Description

-

Inline Pocket Application System for Transparent Invoice/POD Pouches

The Pocket Attaching Equipment is a fully automatic add-on module designed to produce and attach transparent pockets (invoice pouches / POD sleeves) onto courier bags during the production process. This system operates inlinewith existing courier bag making machines, enabling seamless integration for manufacturers who need to add pocket functionality to their current lines.

If the existing courier bag machine does not have a pocket-making function, this unit upgrades it instantly—allowing the user to manufacture courier bags with adhesive or welded transparent pockets in various sizes.

Key Functional Features

✔ Full Inline Operation

Works inline with any courier bag cutting and sealing machine, synchronizing perfectly with production speed and workflow.

✔ Automatic Pocket Production

The system forms the transparent pocket (invoice pouch) from a separate film roll and prepares it for attachment onto the moving courier bag web.

✔ Compatible with Different Pocket Sizes

Designed to attach pockets of various dimensions depending on the courier bag specifications.

✔ Advanced Heat-Air Welding Technology

Equipped with a dual-lane hot air sealing system (double hot air sealing heads) that securely and cleanly welds the transparent pocket onto the courier bag without distortion.

Integrated Units

1. Automatic Unwinding Unit- Fully automatic unwinder for the pocket film roll

- Ensures stable film feeding and tension control

- Converts wide pocket film into the required strip width

- High blade accuracy ensures clean and consistent pocket sizes

- Overlaps and positions the pocket film precisely onto the courier bag web

- Ensures correct placement for consistent product quality

- Two high-efficiency hot-air sealing paths

- Strong and durable welding of pocket to courier bag

- Adjustable heat and air settings for different film types

- Adds pocket-making capability to any courier bag machine

- Perfectly suited for e-commerce, logistics, mailing, and packaging manufacturers

- Fully automatic operation reduces labor and increases efficiency

- Consistent and accurate pocket placement

- High-quality sealing performance

- Works with LDPE, LLDPE and laminated films

- Courier bag production lines requiring invoice pockets

- Upgrading existing machines without replacing the main equipment

- Manufacturers needing multi-size pocket attachment flexibility

-

-

Photo Gallery

info@elesmakina.com

Eles Plastik Makina Otomasyon San ve Tic Ltd. Şti. © All Rights Reserved.

web design grimor

web design grimor

MACHINES AND ANCILLARY EQUIPMENTS

» Manual Paper Core Cutting Machines

» Semi Automatic Core Cutter Machine

» Semi Automatic Core Cutter Machine with CE Covers

» Reel Lifting Equipments

» Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

» Inline Printers

» Plastic Bag Corona Treater

» Woven Bag Corona Treater

» Plastic Granule Mixer

» HDPE-LDPE Recycing Machine

» Inline - Offline Edge Trim Waste Recycling Machine

» Cold Perforation Roller

» Cold Perfotaion Roller With Brush Roller

» Rollers/Cylinders

» 2 Colours Flexo Printing Machine

» Duplex System Slitter Rewinder Machine

» Pocket Attaching Equipment for Courier Bag Making Machines

» Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

» Auto Vacuum Loader

» Trim Waste Rewinder For Extruders

» Accessories

» Spare Parts