- Manual Paper Core Cutting Machines

- Semi Automatic Core Cutter Machine

- Semi Automatic Core Cutter Machine with CE Covers

- Reel Lifting Equipments

- Fully Automatic Paper Core Cutting Machine With Auto Loading and Auto Unliading

- Inline Printers

- Plastic Bag Corona Treater

- Woven Bag Corona Treater

- Plastic Granule Mixer

- HDPE-LDPE Recycing Machine

- Inline - Offline Edge Trim Waste Recycling Machine

- Cold Perforation Roller

- Cold Perfotaion Roller With Brush Roller

- Rollers/Cylinders

- 2 Colours Flexo Printing Machine

- Duplex System Slitter Rewinder Machine

- Pocket Attaching Equipment for Courier Bag Making Machines

- Roll to Roll Unwinding Rewinding Machine (Doctoring Machine)

- Auto Vacuum Loader

- Trim Waste Rewinder For Extruders

- Accessories

- Spare Parts

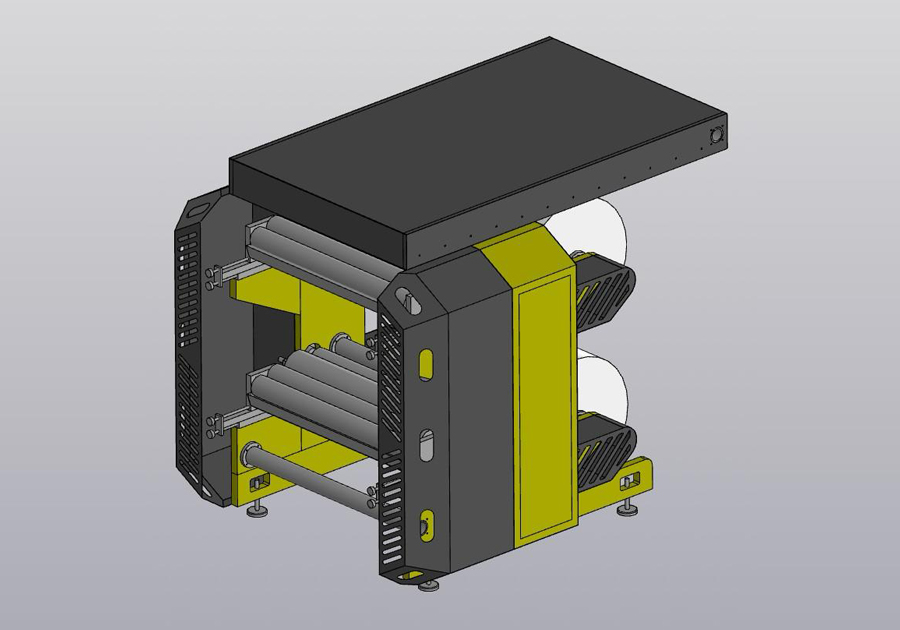

2 Colours Flexo Printing Machine

Model: EMP-1100/2

Model: EMP-1100/2Machine Name: TWO COLOURS FLEXO PRINTING MACHINE

-

Description

-

1. GENERAL DESCRIPTION

· 2-Colour Flexographic Printing Machine

· Printing Configurations:

o 2+0 (two colours on one side)

o 1+1 (one colour per each side)

· Web Widths:

o Printing Width: 1,100 mm

o Product Width: 1,200 mm

o Idler Roller Width: 1,300 mm

· Printing System:

o Rubber rollers + chrome-anilox roller system

o High ink transfer stability

· Machine Speed:

o Maximum 150 m/min production speed

2. DRIVE & MOTION SYSTEM

· Servo Motors in each colour section

· Servo Motor in Rewinder for fully synchronized motion control

· Ensures high precision and stable tension at all speeds

3. UNWINDER UNIT

· One Reel Unwinder Unit

· Magnetic Powder Brake System for stable web tension

· Safety Chucks:

o High-strength, high-speed resistant

· Air Shaft:

o 3” (76 mm) strong, high-speed resistant air shaft

· Automatic Edge Guiding System

· Automatic Tension Control using load-cell feedback

4. REWINDER UNIT

· One Reel Rewinder Unit

· Servo-Driven Rewinder for precise web winding

· Automatic Tension Control with ballerina-dancer system

· Ensures uniform roll hardness and perfect winding structure

5. DRYING SYSTEM

· Optional Heated or Non-Heated strong airflow drying system

· High-efficiency blower design

· Suitable for solvent-based and water-based inks

6. PRINT-CLICHE SYSTEM

· Print-Cliche Roll Lifting Mechanism:

o Automatically lifts the cliche roller when the machine stops

o Prevents ink marks and print defects

· Includes 1 set of any-size cliche rolls free of charge

7. MATERIAL HANDLING & SAFETY

· Strong mechanical frame

· Optimized roller layout for stable web path

· Safety devices integrated at critical points

· High-speed resistant mechanical parts in all rotating zones

SUMMARY – KEY ADVANTAGES

· High-speed 150 m/min production

· Full-servo colour units and rewinder

· Dual printing capability (2+0 / 1+1)

· Automatic tension, edge guiding, and synchronized web control

· Chrome anilox + rubber roll system

· Efficient drying system (heated optional)

· Heavy-duty unwinder/rewinder with safety chucks

-

-

Photo Gallery

web design grimor